ask for quote

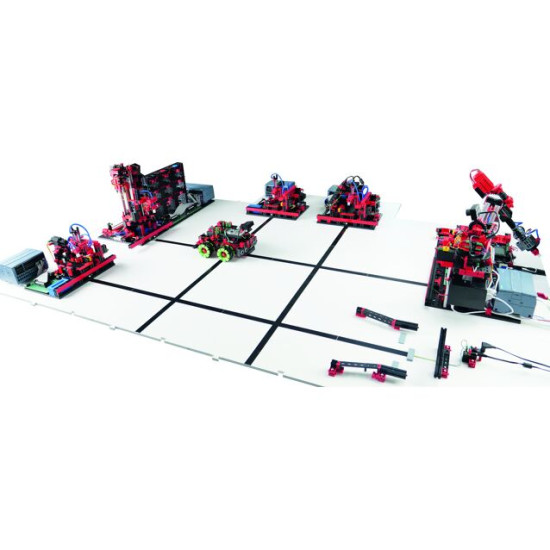

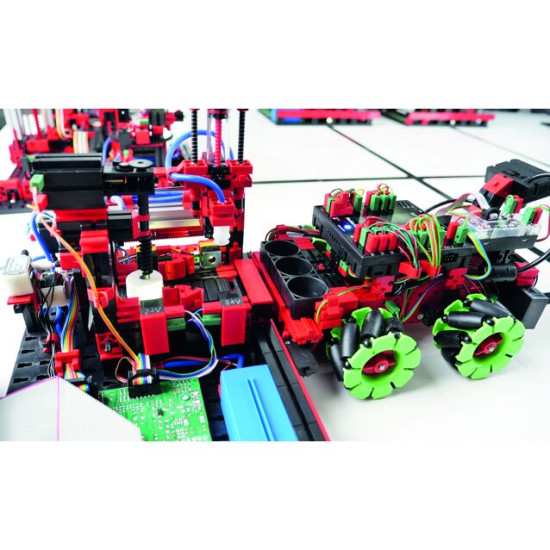

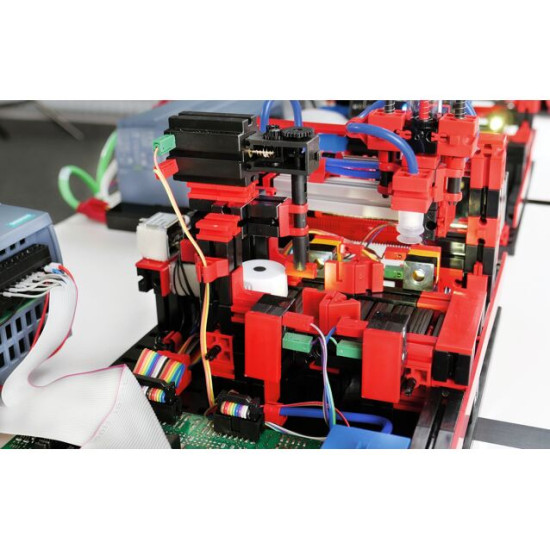

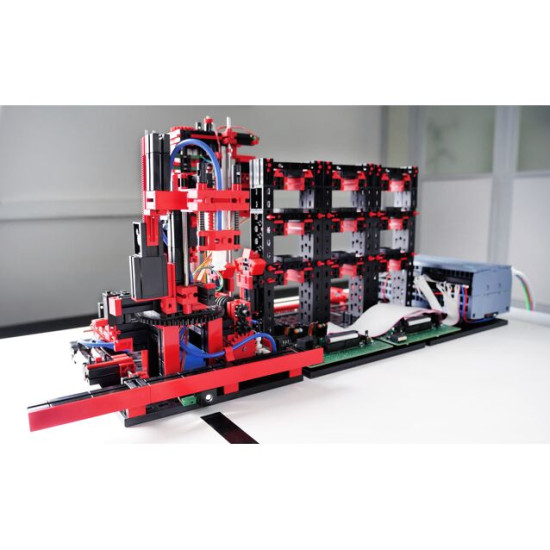

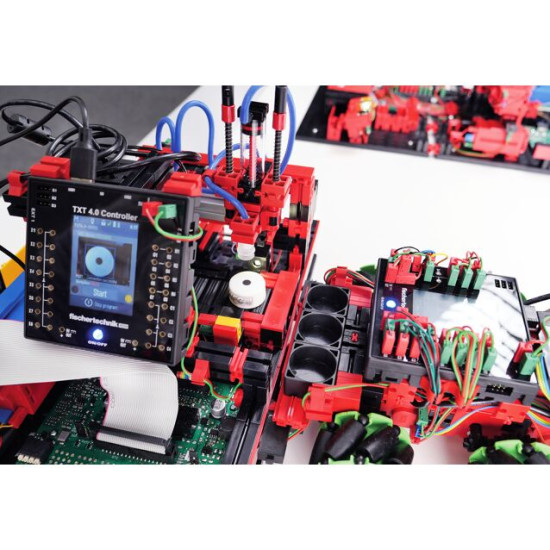

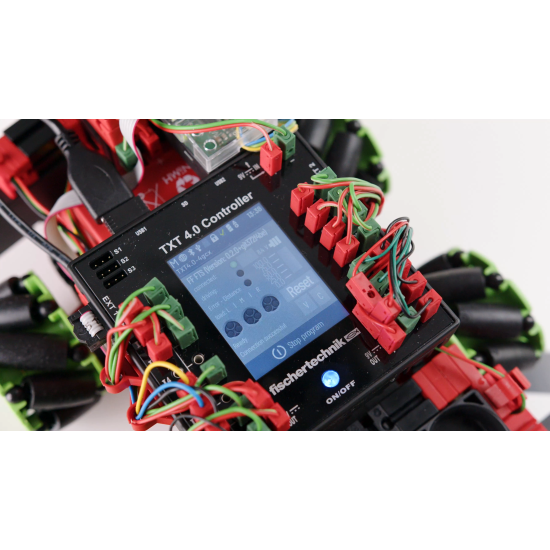

fischertechnik Agile Production Simulation