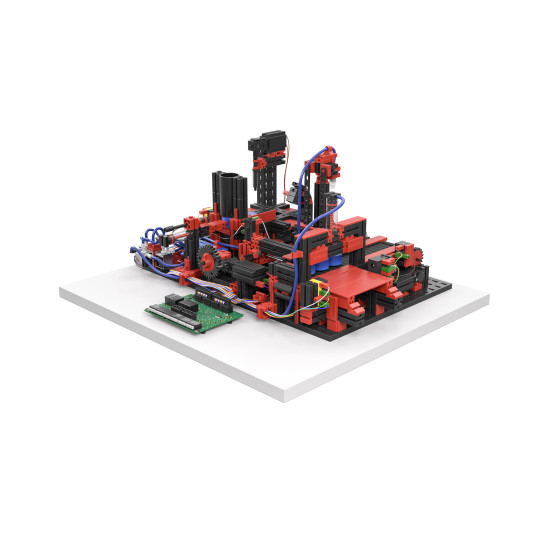

fischertechnik Production Line 24V DC

The fischertechnik Production Line 24V simulates a series of linked

manufacturing steps. At the beginning, the workpieces are loaded onto a

rotary indexing table with four stations using a pneumatic slider from a

magazine. The rotary indexing table transports the workpieces step by

step to the drilling and welding stations, where the workpieces are

processed. In the final station of the rotary indexing table, a vacuum

suction gripper removes the processed workpieces and places them on a

conveyor belt. This conveyor transports the workpieces to the

palletizing unit, where 3 workpieces are collected and then pushed onto a

pallet.

The Production Line 24V includes a comprehensive PLC

course that uses the physical model to create a lasting learning

experience for PLC programming. At the end of the course, the learner

will be able to wire the Production Line 24V independently and program

it in function block diagram or structured text. In a safe, yet

industry-real environment, the learner builds up know-how that can be

used for real machine programming and commissioning. The didactic

concept covers all the essential steps from wiring using a circuit

diagram and creating a flowchart to programming (FBD or SCL) and

commissioning the model. Thanks to the action-oriented approach of this

training model, participants not only develop a deep understanding of

PLC programming, but also the ability to master complex control tasks

independently. The model promotes hands-on learning, creativity and

problem-solving skills, optimally preparing participants for the demands

of industrial practice.

Control system:

- 24V model prepared for control with a PLC

- PLC requirements: 8 digital inputs and 10 digital outputs 24V

- PLC programming course designed for structured text and function chart

- Production line with rotary indexing table, gripper robot, two processing stations and palletizing station

- Ideal training, simulation and demonstration model for vocational training and further education

- Fully assembled 24V training model, mounted on a sturdy wooden board

- Includes comprehensive PLC course

- ATTENTION: A 24V PLC controller is absolutely essential for operation

Content:

5x mini motor

5x push button

5x light barrier LED

4x phototransistor

3x solenoid valve

4x pneumatic cylinder

Compressor

Conveyor belt

This model is also available as a starter set with Siemens S7-1200. This PLC is also suitable for other training models. The PLC in this starter set is pre-wired for use with both the Bending Machine 24V (571911) and the Production Line 24V (571910).

> Extensive PLC course for the training model (EN / DE): download

- Stock: In Stock

- Model: 571910

- EAN: 4048962516715